MIST REMOVAL – HALL VENTILATION

During the paper sheet formation are generated mists due to high flow of water sprayed from this process.

These mists can create some drip, fibers accumulation and deterioration of the machine building hygrothermal condition.

The characteristics of these mists require the use of removing devices in the areas where they are generated.

The mists have to be conveyed to the outside and expelled into the atmosphere after a process of separation of water and paper fibers contained in the fluid.

To obtain this we use fans with special separators that can be cyclone or fins type.

Fins separators that have an higher efficiency, are equipped with an automatic washing system, able to remove the material separated from the air flow.

The machine building ventilation system has the function to control and to assure the proper air balance between the inlet and outlet air flow from the building.

This to avoid an excessive depressurization of the building due to machine air extraction systems.

Furthermore it has to guarantee the proper hygrothermal conditions in the working area for the machine crew.

The energy contained in the hood exhaust air can be used for heating of the machine building inlet air.

During the winter season the external air has to be heated to avoid superficial condensations in the building.

Lario Energy can supply a wide range of auxiliary systems such as:

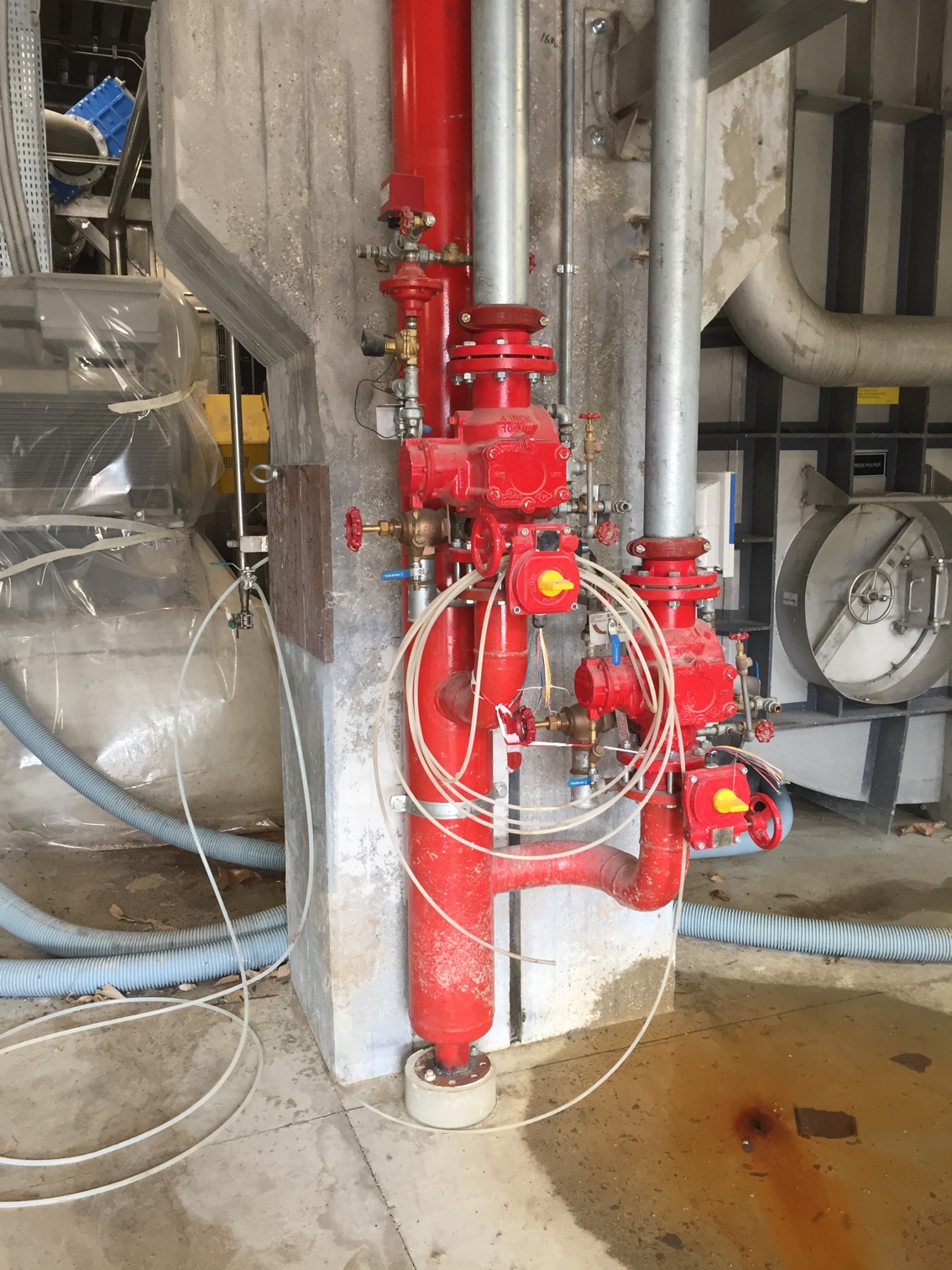

- water and steam fire fighting systems integrated in the hood,

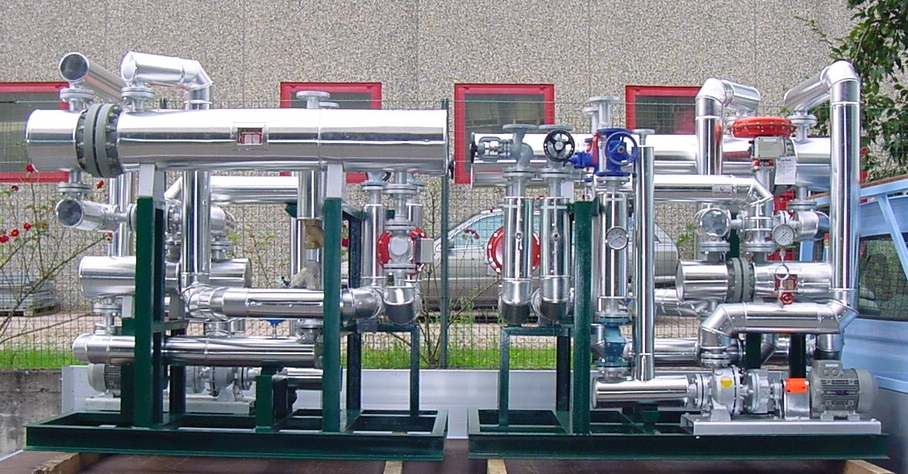

- feeding and control systems for steam boxes,

- premanufactured control units for calenders heating and cooling;

- desuperheater for steam;

- gas and steam drying systems for coating machine.